Wastewater & Liquid Waste Services for Food & Beverage

Protecting production uptime. Ensuring compliance. Managing high-strength and variable waste streams.

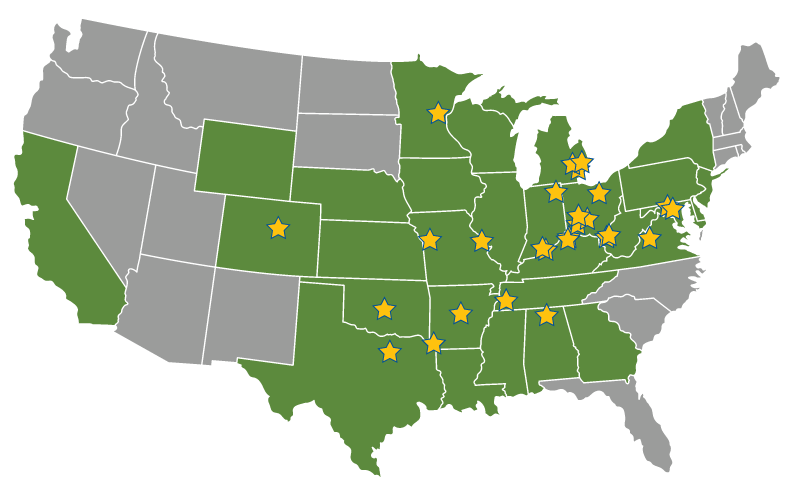

Valicor supports food and beverage producers across the United States with reliable, compliant wastewater treatment, liquid waste management, and bulk waste disposal solutions. Our national network of centralized wastewater treatment (CWT) facilities helps processors handle variable, high-strength organic loads, seasonal production changes, sanitation wastewater, and byproduct liquid streams safely and cost-effectively.

Whether you operate large-scale food processing plants, beverage bottling locations, dairy facilities, breweries, or packaged goods operations, Valicor ensures your wastewater is managed in a compliant, controlled, and sustainable way.

Why Liquid Waste Management Matters for Food & Beverage Processing

Food and beverage facilities generate a wide range of high-strength, variable, and sanitation-driven wastewater streams that must be managed safely and compliantly to protect production uptime and meet regulatory requirements. Critical wastewater challenges often include:

- High-COD/BOD organic loads from food residues, syrups, starches, proteins, and sugars

- FOG (fats, oils, grease) and emulsified waste from cooking, processing, and sanitation

- CIP (clean-in-place) washdowns containing detergents, caustics, sanitizers, and disinfectants

- Brines, saline washes, and salt-heavy wastewater from curing, rinsing, and preservation processes

- Dairy, fermentation, and yeast byproducts that create high variability in waste strength

- Equipment and tank cleaning wastewater that fluctuates throughout production cycles

- Off-spec or expired product disposal requiring secure, compliant destruction

- Cooling water, boiler blowdown, and utility-system wastewater tied to plant operations

As production capacity increases, product variety expands, and regulatory pressure rises, food and beverage processors must ensure wastewater is handled in a controlled, compliant, and cost-efficient manner—without disrupting production schedules or sanitation cycles.

Wastewater Services for Food & Beverage Manufacturers

Centralized Wastewater Treatment (CWT)

Advanced treatment capabilities for high-volume, high-variability F&B wastewater, including:

- High-COD/BOD wastewater

- FOG-heavy and emulsified oily waste

- Organic-rich wash water from production and sanitation

- CIP rinses with detergents and sanitizers

- Brine, sugar, syrup, and flavor-containing wastewater

- pH adjustment for acidic/caustic cleanouts

Product Destruction & Brand Protection

Secure management of:

- Finished goods needing destruction

- Recalled or contaminated beverages and food products

- Off-code, mislabeled, or package-damaged items

- Quality hold disposal with full compliance and documentation

Transportation & Logistics

Nationwide, reliable liquid-waste transport:

- Vacuum trucks

- Bulk tankers

- Dedicated routes for large generators

- Emergency or short-notice pickups

- Full manifesting and compliance records

Bulk Liquid Disposal

Reliable treatment or disposal of:

- Off-spec or expired food and beverage products

- Tank cleanouts and residual liquids

- Ingredient flush water and batch-change wastewater

- Beverage waste from bottling lines and QA rejections

- Dairy and fermentation waste streams

Hazardous Wastewater Support

For F&B facilities using chemicals for:

- CIP sanitation

- Equipment descaling

- Detergents, disinfectants, and caustics

- Cleaners and industrial-strength degreasers

Acceptance varies by site; documentation required.

Recycling & Resource Recovery Opportunities

When applicable:

- Organic-rich wastewater beneficial reuse

- Grease and oil recovery

- Recycling options for some food byproducts (case-by-case)

Sustainability & Resource Recovery for Food & Beverage Processors

Valicor supports food & beverage processors in improving environmental performance through:

- Oil recovery and reuse

- Solids recovery

- Water reuse and recycling

- Waste minimization strategies

We help companies align with corporate sustainability goals, ESG reporting, and circular-economy initiatives.

Supporting Food & Beverage Processing Facilities

Valicor works with a broad range of food and beverage operations, including:

- Food processing plants (meat, poultry, produce, frozen, prepared foods)

- Beverage manufacturing and bottling (soft drinks, water, juices)

- Breweries, distilleries, and fermenters

- Dairy processors and creameries

- Packaged foods, canned goods, and ready-to-eat (RTE) facilities

- Bakeries and grain/ingredient processors

- Snack manufacturing and confectionery plants

- Pet food and animal nutrition producers

- Contract manufacturers, co-packers, and private-label producers

- Ingredient blending, food additives, flavors, and formulations

- Sanitation, janitorial, and equipment-cleaning operations

Common Waste Streams Valicor Handles

Food and beverage facilities generate unique high-strength and organic-rich wastewater streams. Valicor can safely manage:

- High-COD/BOD wash water

- Fats, oils, and grease (FOG) and emulsified wastewater

- Protein- and starch-rich wastewater

- CIP (clean-in-place) washdowns

- Sanitizer, detergent, and disinfectant rinse water

- Brine wastewater and salt solutions

- Yeast, fermentation byproducts & residual liquids

- Beverage waste (off-spec, expired, contaminated products)

- Dairy wastewater (lactose, whey, milk-based streams)

- Flavorings, syrups, concentrates, colorants

- Sugar-rich wastewater and sticky waste streams

- Cooling water, boiler blowdown, and utility wastewater

- Equipment washout and tank cleaning wastewater

- Off-spec batched product, flush water, and start-up/shutdown waste

Valicor's Services Go Beyond Simply Treating Waste

Regulatory Pressure & Compliance

- NPDES discharge limits

- RCRA hazardous waste requirements

- Local POTW restrictions

- Documentation and manifest accuracy

Cost & Operational Efficiency

- Optimizing internal treatment costs

- Streamlining plant operations

- Avoiding unplanned downtime

- Managing variable waste chemistry with predictable pricing

Environmental & ESG Goals

- Lowering waste disposal impacts

- Increasing resource recovery

- Reducing GHG emissions through optimized logistics

Nationwide Coverage for Datacenters

Valicor operates one of North America’s largest networks of centralized wastewater treatment facilities, enabling reliable support for hyperscale, enterprise, and colocation datacenters nationwide. We service customers within a 200-mile radius of every Valicor location, ensuring fast response times and consistent, compliant handling of all cooling and utility-related wastewater.

Whether you operate high-density AI compute facilities, regional edge datacenters, or multi-site national deployments, Valicor provides scalable, dependable wastewater and liquid waste solutions that protect uptime and support continuous operations, no matter where your datacenters are located.

Regions We Serve

Midwest Region

Supporting major food/beverage production corridors including:

- Cincinnati

- Dayton

- Columbus

- Cleveland

- Toledo

- Detroit

- Ann Arbor

- Indianapolis

- Fort Wayne

- South Bend

- Northern Kentucky & Central Kentucky production zones

Ideal for: meat processors, beverage manufacturers, frozen foods, snack foods, distribution hubs.

Southeast Region

Serving fast-growing food manufacturing clusters such as:

- Nashville

- Huntsville

- Birmingham

- Chattanooga

- Memphis

- Louisville

- Lexington

- Western Georgia and Eastern Mississippi

Ideal for: poultry & protein processors, bakeries, beverage bottlers, co-packers.

Texas & South-Central Region

Reaching key food production and distribution hubs:

- Dallas–Fort Worth

- Houston Metro

- Austin/San Marcos corridor

- Waco

- Tyler & Longview

- Shreveport

- Texarkana

Ideal for: beverage canning, dairy, bakery, snacks, packaged foods, and large logistics networks.

Mid-Atlantic Region

Coverage across:

- Baltimore

- Washington, D.C.

- Northern Virginia

- Frederick

- Hagerstown

- Harrisburg

- Southern Pennsylvania

Ideal for: RTE foods, beverage bottling, ingredient blending, snack foods, baked goods.

Rocky Mountain & Central Plains Region

Serving expanding F&B processing in:

- Denver

- Boulder

- Fort Collins

- Colorado Springs

- Greeley

- Cheyenne

Ideal for: dairy, beverage, natural foods, craft beverages, and regional food manufacturers.

Additional Service Regions

- Western Wisconsin

- Southern Illinois

- Western Pennsylvania

- Eastern Kentucky

- Northern Mississippi

- Missouri (Kansas City & St. Louis food-production corridors)

Our Facility Network

Alabama

Huntsville | North Alabama (Hanceville)

Arkansas

Colorado

Indiana

Kentucky

Burlington | Louisville – Port Rd | Louisville – Tucker Rd

Maryland

Williamsport – Elliott | Williamsport – Powerhouse | Westminster

Michigan

Minnesota

Missouri

Ohio

Monroe | Dayton | Mansfield | Middletown – Cincinnati-Dayton Rd | Middletown – Lefferson Rd

Oklahoma

Tennessee

Texas

Virginia

West Virginia

Extended Coverage Areas

These extended areas fall within approximately a 200-mile service radius of one or more Valicor facilities:

Major Metros: Atlanta, Nashville, St. Louis, Kansas City, Houston, Dallas, Cincinnati, Cleveland, Columbus, Indianapolis, Detroit, Minneapolis–St. Paul, Baltimore, Washington DC, Denver, Oklahoma City, Memphis.

Industrial Corridors: Gulf Coast petrochemical corridor, Midwest manufacturing belt, Ohio River Valley industrial region, Central Texas manufacturing corridor, Northern Kentucky manufacturing zone, Southern Indiana industrial region, Colorado Front Range.

Multi-State Coverage Zones:

Southern Illinois, Eastern Missouri, Western Pennsylvania, Western Wisconsin, Northern Mississippi, Eastern Kentucky, Southern Ohio, Northern West Virginia, Central Maryland, Eastern Arkansas, Southern Michigan, Northern Texas, Western Tennessee.

Ready to Get Started?

Let’s design a waste management plan that keeps your semiconductor or electronics operation compliant, efficient, and sustainable.

Contact Us Today

Connect with our team to request profiling, schedule service, or learn more about our nationwide capabilities.

Since 2024, Valicor has been a participant and supporter of the United Nations Global Compact, demonstrating our commitment to sustainable development.

Interested in learning more about Valicor's commitment to sustainability?

Download Our Complete 2025 Sustainability Report

Ready to Talk with Us?

Start a conversation with us today!