Waste & Wastewater Services for

Electronics & Semiconductor Manufacturing

Trusted Wastewater Treatment & Bulk Liquid Disposal for High-Tech Manufacturing Environments

Electronics and semiconductor manufacturing operations generate some of the most complex wastewater and liquid waste streams in the industrial sector, from CMP slurries and heavy-metal rinse waters to solvents, acids, cooling fluids, and ultra-pure water system blowdown. Valicor provides nationwide centralized wastewater treatment, bulk liquid disposal, hazardous and non-hazardous waste handling, transportation, and sustainability-focused resource recovery for semiconductor fabs, PCB facilities, electronics assembly plants, battery manufacturers, and component suppliers across the United States.

Why Electronics & Semiconductor Manufacturers Choose Valicor

Experience with High-Tech Waste Profiles

Deep experience managing sensitive, high-purity waste streams including slurries, solvents, acids, and trace-metal wastewater.

Centralized Wastewater Treatment (CWT)

Cost-effective, compliant treatment for large-volume wastewater generated across lithography, plating, CMP, and cooling processes.

Bulk Liquid Disposal Expertise

Nationwide handling, transportation, and disposal for both hazardous and non-hazardous liquids.

Regulatory Confidence

Support for complex environmental regulations including RCRA, CAA, state discharge permits, and local industrial pretreatment requirements.

High-Volume, High-Reliability Logistics

Valicor’s transportation network supports 24/7 facilities with scheduled pickups, manifesting, profiles, and documentation.

Sustainability & Resource Recovery

Recovery and reuse of valuable materials including copper, precious metals, solvents, and glycol to support corporate ESG goals.

Comprehensive Wastewater Solutions for Electronics & Semiconductor Manufacturers

Advanced Metals Removal & High-Purity Wastewater Treatment

Electronics and semiconductor processes generate wastewater with trace metals and ultra-low discharge limits. Valicor provides treatment solutions engineered for:

- Metals-bearing rinse waters (copper, nickel, chromium, lead, tin, silver, zinc)

- Etching and plating chemistry waste

- Lithography developer and photoresist residues

- Spent process solutions from PCB, semiconductor, and microelectronics lines

- Waste streams requiring precise pH neutralization and metals precipitation

Our centralized wastewater treatment (CWT) facilities support consistent, compliant treatment for complex, multi-step manufacturing operations.

Acid & Caustic Waste Treatment

Semiconductor and electronics facilities rely heavily on corrosive chemistries. Valicor accepts a wide range of acidic and alkaline wastewater requiring careful handling, dilution, or neutralization.

Typical waste streams include:

- HF, HNO₃, HCl, and H₂SO₄ acid solutions

- High-pH cleaners, alkaline etchants, and caustic developers

- Spent decontamination or surface prep chemistries

- Acid/alkali mixtures requiring controlled pH adjustment

This is a critical support service for fabs, PCB plants, and component manufacturers.

Bulk Liquid Disposal

Valicor manages a wide range of non-hazardous and certain hazardous liquid wastes generated during electronics and semiconductor production.

- Common waste types include:

- Off-spec or expired process chemicals

- Tank cleanout liquids and rinses

- Spent stripping and cleaning solutions

- Aqueous mixtures containing metals, solvents, or surfactants

- Solvent-contaminated water

We ensure compliant, documented disposal that helps manufacturers maintain operational uptime.

Transportation & Logistics Services

Valicor provides reliable, nationwide logistics for semiconductor and electronics manufacturers requiring consistent, secure movement of liquid waste:

- Vacuum trucks for high-solids or slurry pickup

- Bulk tankers for high-volume wastewater

- Scheduled and dedicated route service

- Rapid-response and emergency pickup options

- Full tracking, manifests, and compliance documentation

This ensures higher uptime and reduces in-house waste handling risks for manufacturing teams.

CMP Slurry & High-Precision Solids Waste Management

Chemical Mechanical Planarization (CMP) generates highly specialized slurry waste streams containing abrasive solids and trace metals. Valicor provides safe, efficient handling and disposal of:

- Silica, alumina, and ceria-based CMP slurry

- High-solids wastewater and particulate-heavy streams

- Filtration byproducts and captured fines

- Rinse waters containing polishing agents and suspended solids

We ensure stable, compliant management of one of the most challenging waste categories in semiconductor fabrication.

Cooling Water, Glycol & Utility Waste Streams

High-tech manufacturing requires large-scale cooling and environmental control systems. Valicor supports safe and compliant treatment or disposal of:

- Glycol mixture waste from cooling loops

- Cooling tower blowdown

- Chiller water contaminated with metals or particulates

- Utility rinse waters and non-process liquid waste

This complements growing ESG requirements around reducing water consumption and preventing contamination.

Hazardous Wastewater & Liquid Waste Solutions

Many semiconductor and electronics processes create regulated or characteristic hazardous wastes. Valicor supports safe, compliant management of:

- Ignitable or solvent-containing wastewater

- RCRA-characteristic acidic or caustic liquids

- Metal-contaminated hazardous wastewaters

- Solvent/aqueous mixtures or residues

- Photoresist, developer, and lithography chemistry wastewaters

All handling is documented, tracked, and compliant with federal and state regulations.

Water Reuse & Sustainability Support

High-tech manufacturers are among the most water-intensive operations in the world. Valicor assists customers in meeting sustainability goals through:

- Waste volume reduction strategies

- Resource and water recovery opportunities

- Waste minimization through optimized consolidation

- Support for ESG reporting and environmental metrics

Our solutions reduce environmental impact while improving operational efficiency.

Sustainability & Resource Recovery for Electronics & Semiconductor manufacturers

Valicor supports chemical producers in improving environmental performance through:

- Oil recovery and reuse

- Solids recovery

- Water reuse and recycling

- Waste minimization strategies

We help companies align with corporate sustainability goals, ESG reporting, and circular-economy initiatives.

Supporting Electronics & Semiconductor Manufacturers

Valicor helps electronics and semiconductor facilities protect uptime, improve environmental compliance, and safely manage high-purity and high-sensitivity waste streams. We support:

- Semiconductor wafer fabrication plants (8”, 12”, advanced nodes)

- Printed circuit board (PCB) manufacturers

- Electronics assembly and component manufacturing

- Battery, energy-storage & EV component production

- Solar panel and photovoltaic cell manufacturers

- Plating, etching & surface finishing operations

- Molded plastics, connectors, wiring, and electronic housings

- Display, LED & lighting manufacturers

- High-purity chemical supply chain partners

Common Waste Streams Valicor Handles:

- Acidic and caustic wastewater

- CMP wastewater and slurries (silica, alumina, ceria)

- Rinse waters containing copper, nickel, chromium, lead, and other metals

- Solvents and solvent-contaminated liquids

- Plating and etching bath solutions

- Photoresist, developer, and lithography chemicals

- Ion-exchange regeneration wastewater

- Cooling tower blowdown and glycol/water mixtures

- Off-spec, expired, or contaminated chemical solutions

- Ultrafiltration and RO reject streams

- Equipment washdown and line-flush wastewater

Valicor's Services Go Beyond Simply Treating Waste

Regulatory Pressure & Compliance

- NPDES discharge limits

- RCRA hazardous waste requirements

- Local POTW restrictions

- Documentation and manifest accuracy

Cost & Operational Efficiency

- Optimizing internal treatment costs

- Streamlining plant operations

- Avoiding unplanned downtime

- Managing variable waste chemistry with predictable pricing

Environmental & ESG Goals

- Lowering waste disposal impacts

- Increasing resource recovery

- Reducing GHG emissions through optimized logistics

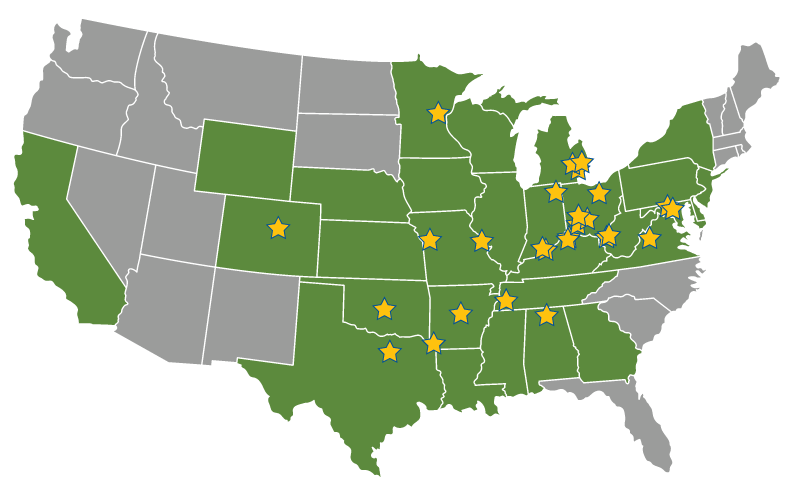

Nationwide Coverage for Electronics & Semiconductor Facilities

Valicor operates one of North America’s largest networks of centralized wastewater treatment facilities. We support electronics and semiconductor operations across the country, servicing customers within a 200-mile radius of every Valicor location.

From wafer fabs and PCB lines to energy-storage and clean-tech manufacturers, we deliver consistent, reliable, and compliant wastewater solutions, no matter where your facilities are located.

Regions We Serve

Midwest Region

Supporting major high-tech manufacturing, electronics assembly, PCB production, and high-purity component fabrication across:

- Columbus, OH (fast-growing semiconductor supply chain hub)

- Cincinnati, OH

- Dayton, OH

- Cleveland, OH

- Toledo, OH

- Detroit, MI (EV battery, electronics, and automation corridor)

- Ann Arbor, MI

- Fort Wayne, IN

- Indianapolis, IN (electronics production + EV component growth)

- South Bend, IN

- Northern & Central Kentucky advanced manufacturing belt

Southeast Region

Serving rapid-growth electronics, EV battery, and high-tech assembly corridors including:

- Huntsville, AL (major electronics, aerospace, and PCB hub)

- Birmingham, AL

- Nashville, TN (electronics assembly + semiconductor supplier expansion)

- Chattanooga, TN

- Memphis, TN

- Tuscaloosa, AL

- Louisville, KY

- Lexington, KY

- Western Georgia & Eastern Mississippi manufacturing corridors

Texas & South-Central Region

Extensive coverage across semiconductor fabrication, electronics assembly, and advanced packaging growth markets:

- Dallas–Fort Worth Metroplex (semiconductor fabrication, PCB, telecom, aerospace electronics)

- Austin, TX (major U.S. semiconductor and advanced logic hub)

- Houston Metro (electronics, petrochemical-based chemistries, cooling water operations)

- San Antonio, TX

- Waco, TX

- Longview & Tyler, TX

- Texarkana, TX/AR

- Shreveport, LA

- Beaumont & Port Arthur, TX

- Central & North Texas high-tech manufacturing zones

Mid-Atlantic Region

Supporting high-tech, data-center, and electronics manufacturing corridors across:

- Baltimore, MD

- Washington, D.C.

- Northern Virginia (major data-center corridor + electronics suppliers)

- Frederick, MD

- Hagerstown, MD

- Harrisburg, PA

- Southern Pennsylvania advanced manufacturing belt

- Eastern West Virginia

Rocky Mountain & Central Plains Region

Extensive coverage supporting electronics manufacturing, plastics molding, telecom equipment production, and data-center infrastructure:

- Denver, CO

- Boulder, CO (high-tech, optics, RF electronics)

- Fort Collins, CO (semiconductor and electronics engineering corridor)

- Colorado Springs, CO

- Greeley, CO

- Cheyenne, WY

- Southern Wyoming

- Western Kansas manufacturing region

Additional Service Regions

Supporting additional high-tech and electronics-related markets including:

- Western Wisconsin (electronics assembly + precision molding)

- Southern Illinois

- Western Pennsylvania (Pittsburgh tech corridor)

- Eastern Kentucky (electronics + battery supply chain growth)

- Northern Mississippi

- Missouri high-tech manufacturing corridor (Kansas City & St. Louis metros)

Our Facility Network

Alabama

Huntsville | North Alabama (Hanceville)

Arkansas

Colorado

Indiana

Kentucky

Burlington | Louisville – Port Rd | Louisville – Tucker Rd

Maryland

Williamsport – Elliott | Williamsport – Powerhouse | Westminster

Michigan

Minnesota

Missouri

Ohio

Monroe | Dayton | Mansfield | Middletown – Cincinnati-Dayton Rd | Middletown – Lefferson Rd

Oklahoma

Tennessee

Texas

Virginia

West Virginia

Extended Coverage Areas

These extended areas fall within approximately a 200-mile service radius of one or more Valicor facilities:

Major Metros: Atlanta, Nashville, St. Louis, Kansas City, Houston, Dallas, Cincinnati, Cleveland, Columbus, Indianapolis, Detroit, Minneapolis–St. Paul, Baltimore, Washington DC, Denver, Oklahoma City, Memphis.

Industrial Corridors: Gulf Coast petrochemical corridor, Midwest manufacturing belt, Ohio River Valley industrial region, Central Texas manufacturing corridor, Northern Kentucky manufacturing zone, Southern Indiana industrial region, Colorado Front Range.

Multi-State Coverage Zones:

Southern Illinois, Eastern Missouri, Western Pennsylvania, Western Wisconsin, Northern Mississippi, Eastern Kentucky, Southern Ohio, Northern West Virginia, Central Maryland, Eastern Arkansas, Southern Michigan, Northern Texas, Western Tennessee.

Ready to Get Started?

Let’s design a waste management plan that keeps your semiconductor or electronics operation compliant, efficient, and sustainable.

Contact Us Today

Connect with our team to request profiling, schedule service, or learn more about our nationwide capabilities.

Since 2024, Valicor has been a participant and supporter of the United Nations Global Compact, demonstrating our commitment to sustainable development.

Interested in learning more about Valicor's commitment to sustainability?

Download Our Complete 2025 Sustainability Report

Ready to Talk with Us?

Start a conversation with us today!